Groeneveld Twin XL

Developed for demanding applications and severe conditions. Specifically used for larger applications.

The Twin XL is a dual-line automatic lubrication system for large machines used for earthmoving and mining operations in extreme conditions. As a parallel operation with two lines, Twin systems pump GreenLube grease efficiently to all points. With an extra large reservoir holding 20 litres.

Groeneveld supplies a barrel pump with reservoir volumes from 40 to 200 liters. The major benefit will be that the user rarely needs to refill the reservoir.

- Grease output and grease delivery independent of ambient temperature and grease viscosity

- Due to the relatively low work pressure, the quality of the grease is preserved

- Modern pump with real-time clock, memory, CAN-Bus connection and follower plate

- High quality metering units and distribution blocks

- Standard with in-cab display

- Available with reservoir volumes ranging from 40 to 200 litres

- Easy to program, install and extend

- The filling coupling with filter prevents contamination during filling

- Easily extended to grippers, excavation buckets and other equipment pieces through quick couplers

- Suitable for biodegradable grease

Follower Plate

· The follower plate ensures that all the grease in the reservoir is used. This means that the reservoir wall remains clean, allowing you to check the grease level visually. Ageing of the grease as a result of oxidation is also prevented.

Reservoir

· The Twin XL is similar to the Twin however it is made of steel. The reservoir volume is 20 litres.

Filler coupling with filter

· The filling coupling with grease filter prevents contamination of the grease during filling.

Pump housing

· The pump is made of hard anodised aluminium and nylon reinforced, containing the control unit, memory database and minimum level indicator.

Working Principle

A Twin XL works the same as a Twin. The Twin XL system consists of a pump with a grease reservoir, a main line network to the distribution blocks with metering units and a secondary line network to the lubrication points. The grease is pumped into the distribution blocks via a double main line network. The metering units supply the exact amount of grease to each of the lubrication points. The pump switches off once the pressure in all metering units is at least 100 bar. As a result, the right amount of grease is provided at each lubrication point, independent of the counter-pressure, temperature or viscosity of the grease.

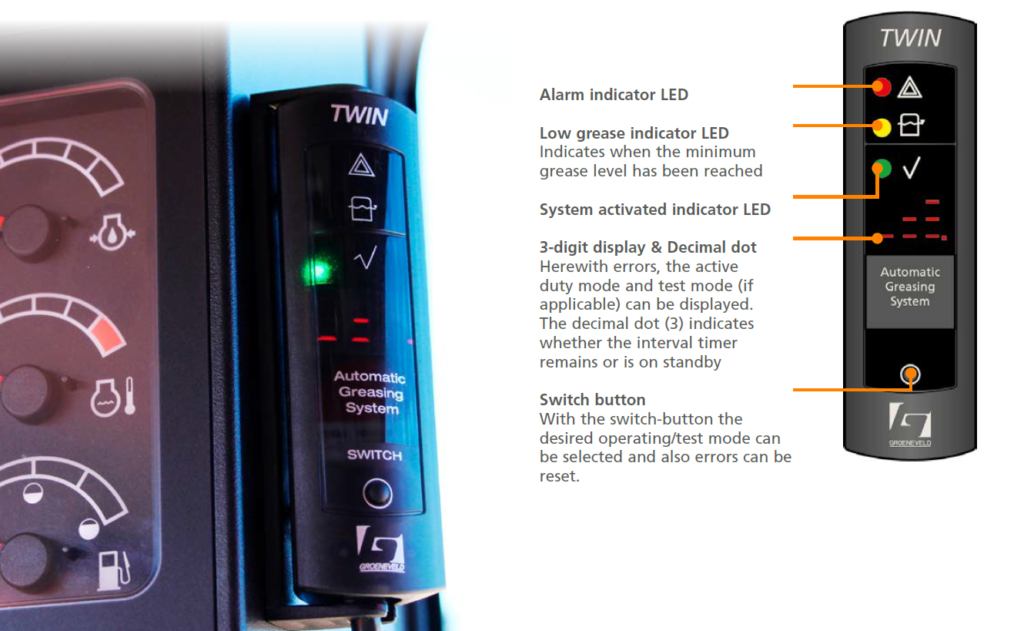

Twin in-cab display

In order to check the status of the system, the driver or operator does not have to leave the cabin. The in-cab display will show system messages in the cabin. This will allow an easy and fast diagnosis of the system, as well as remote assistance.