Lubrication Systems for Fixed & Mobile Processing Plant

Below are the different systems from Groeneveld-BEKA. To see more click on the FULL DETAILS for each system or contact us for information.

Application:

- Screening plants

- Crushing plants

- Timber mill plants

- Food processing plants

- Textile processing plants

Twin

Groeneveld-

Preferred system globally

-

Parallel system

-

Precise metering units

-

Optimal Lubrication

-

Retains grease quality

-

Minimal grease wastage

-

4 & 8 litre reservoir

-

Filtered grease coupling

-

Robust pump housing

-

In-cab control unit

-

Easily extended

FULL DETAILS

Groeneveld Twin

SingleLine

Groeneveld-

Strong & Reliable for plant

-

Parallel system

-

Precise metering units

-

Optimal lubrication

-

Retains grease quality

-

Minimal grease wastage

-

4 & 8 litre reservoir

-

Filtered grease coupling

-

Robust pump housing

-

In-cab control unit

-

Extends easily

FULL DETAILS

Groeneveld SingleLine

OnePlus

Groeneveld-

Unique distribution blocks

-

Progressive system

-

Precise metering units

-

Optimal lubrication

-

Retains grease quality

-

Minimal grease wastage

-

4 litre reservoir

-

Filtered grease coupling

-

Robust pump housing

-

FULL DETAILS

Groeneveld OnePlus

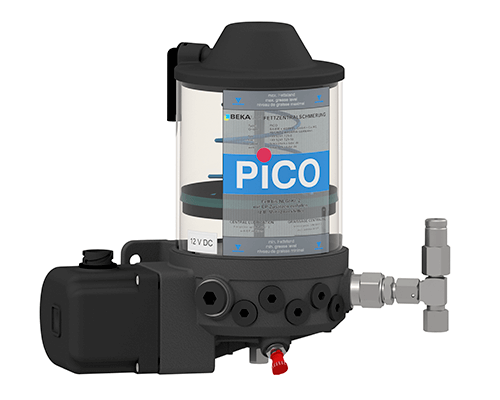

PICO

BEKA-

For smaller plants

-

Progressive system

-

Precise metering units

-

Takes common lubricants

-

Retains grease quality

-

Minimal grease wastage

-

1.2 litre reservoir

-

Can be filled with grease gun

-

Protective housing

-

FULL DETAILS

BEKA PICO

BEKA EP-1

BEKA-

A versatile solution

-

Progressive system

-

Precise metering units

-

Takes common lubricants

-

Retains grease quality

-

Minimal grease wastage

-

4 litre reservoir

-

Filtered grease coupling

-

Heavy duty components

-

External control unit

FULL DETAILS

BEKA EP-1