BEKA PICO

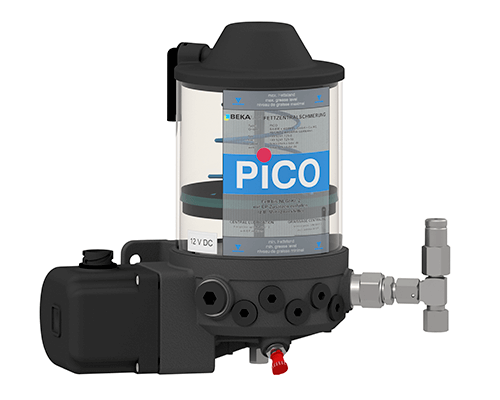

The BEKA Pico lubrication system by Groeneveld-BEKA is an innovative solution for machinery lubrication, designed to provide a compact and efficient solution for a wide range of machinery types.

Benefits of the BEKA Pico lubrication system include:

- Patented multi-line technology that allows for precise and controlled delivery of lubricants to the various components of a machine.

- Highly flexible, with a range of programmable settings that can be customised to suit the specific needs of different machines and applications.

- Compact design that is small enough to fit in tight spaces and can be easily installed in a variety of machinery types.

- Powerful, with the ability to deliver up to 50 bar of pressure, making it suitable for even the most demanding machinery types.

- Easy to use, with a user-friendly touchscreen interface that allows for quick and easy programming and monitoring of the system’s settings.

- Reliable, with automatic shut-off valves, high-pressure relief valves, and advanced monitoring systems that help to ensure smooth operation and prevent costly breakdowns and downtime.

- Sustainable, using only the minimum amount of lubrication needed to keep machinery running smoothly, and minimising waste and environmental impact.

The BEKA Pico lubrication system is an ideal choice for companies that need a reliable, efficient, and sustainable lubrication solution for their machinery. Whether you are operating a fleet of trucks, managing an industrial plant, or running an agricultural operation, the BEKA Pico lubrication system can help keep your machinery running smoothly and efficiently, while also reducing costs and minimising environmental impact.

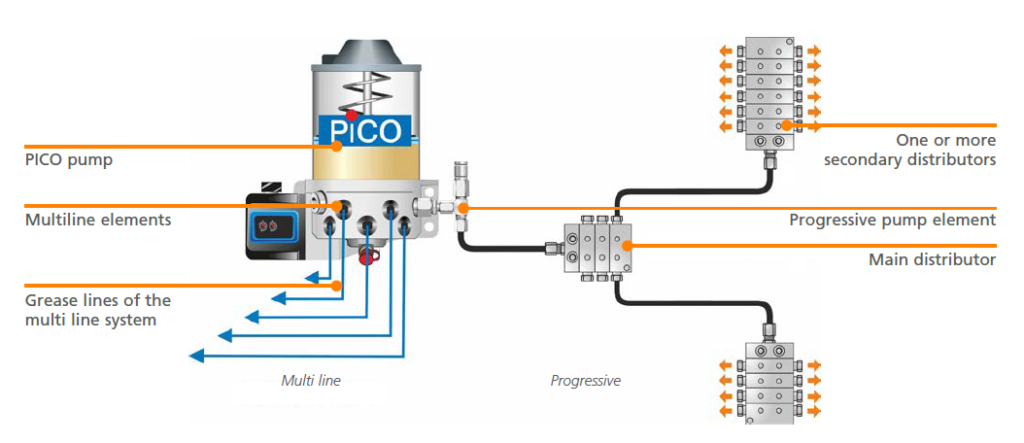

The basic version of the PICO pump supplies lubricant through the progressive outlets to the lube points via one or more progressive distributors. In addition, up to 8 lubrication points can be supplied directly via the multi-line principle. If necessary, the system can be enlarged by a second progressive cycle.

- Very compact design for application with a small number of lubrication points

- Unique combination of two lubrication systems

- Progressive and multi-line technology

- Suitable for all common lubricants from NLGI-000 to NLGI-2

- Flexible extension possibilities

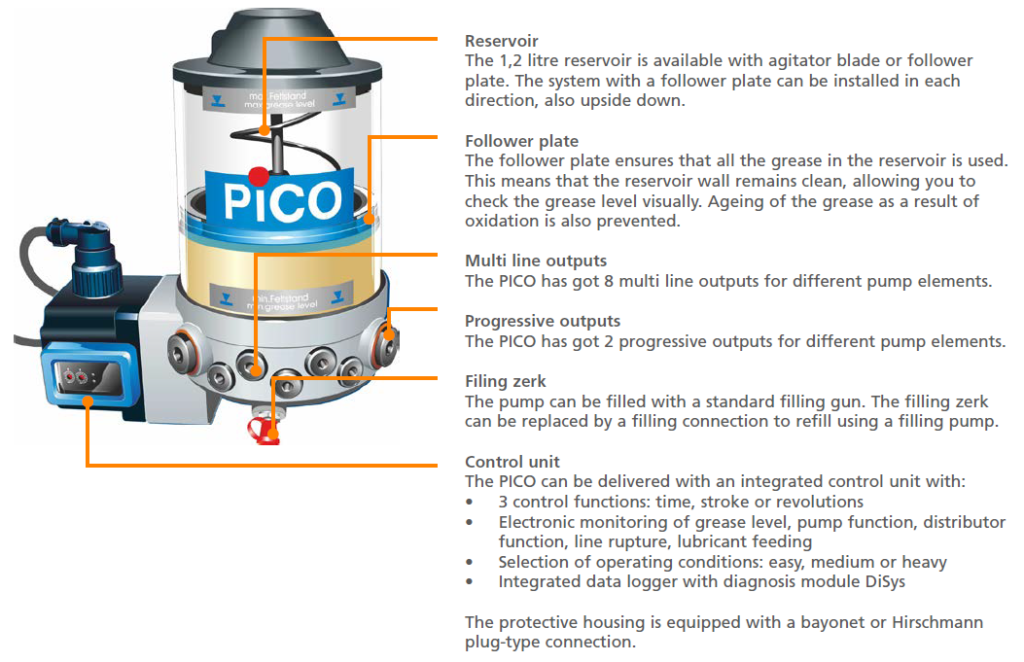

- Follower Plate

- The follower plate ensures that all of the grease in the reservoir is used. This means that the reservoir wall remains clean, allowing you to check the grease level visually. Ageing of the grease as a result of oxidation is also prevented.

Reservoir

- The 1.2 litre reservoir is available with agitator blade or follower plate. The system with a follower plate can be installed in each direction, also upside down.

Multi line outputs

- The PICO has 8 multi line outputs for different pump elements.

Progressive outputs

- The PICO has 2 progressive outputs for different pump elements.

Filling zerks

- The pump can be filled with a standard filling gun. The filling zerk can be replaced by a filling connection to refill using a filling pump.

Control unit

The PICO can be delivered with an integrated control unit with:

- 3 control functions: time, stroke or revolutions

- Electronic monitoring of grease level, pump function, distributor function, line rupture, lubricant feeding

- Selection of operating conditions: easy, medium or heavy

- Integrated data logger with diagnosis module DiSys

The protective housing is equipped with a bayonet or Hirschmann plug-type connection.

Working Principle

When the PICO pump is activated, grease is pumped through the pump elements. The pump elements transfer the grease to main and secondary progressive distributors. The multi-line elements transfer the grease directly to the lubrication points.